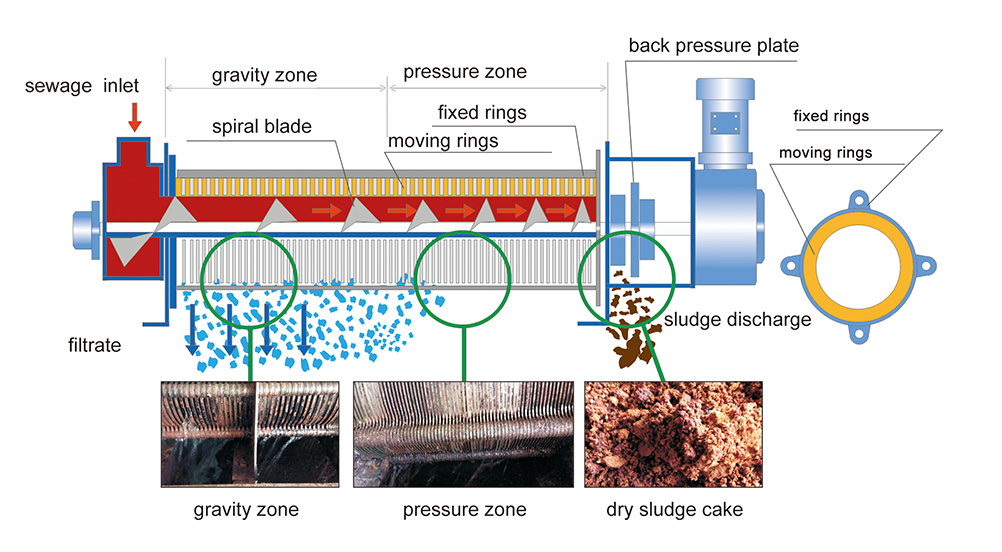

Ka'idar Aiki:

Ana ciyar da sludge mai sharadi a cikin yankin da ake zubar da ruwa daga tankin mai yawo. Yayin da yake ci gaba ta hanyar kunkuntar ramukan da aka kafa ta screw shaft da zoben motsi, matsa lamba yana ƙaruwa kuma a hankali ana matse ruwa.

Ruwan da aka keɓe yana gudana ta cikin rata tsakanin motsi da ƙayyadaddun zobba, waɗanda aka tsaftace ta atomatik ta motsi na zoben da kansu - yana hana shinge da kuma tabbatar da ci gaba da aiki. Ana fitar da kek ɗin da aka matsa daga ƙarshe.

Mabuɗin fasali:

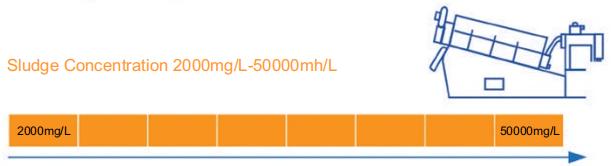

Gabatar da hankali don sludge mai ƙarancin hankali

An sanye shi da farantin karkace na musamman, injin ɗin yana aiwatar da ingantaccen maida hankali, yana mai da shi dacewa musamman don magance sludge mai ƙarancin hankali. Ta maye gurbin nagartaccen nau'in nau'in nau'in nauyi na gargajiya da kuma haɗa matakan flocculation da tsarin tattarawa, yana sauƙaƙe maganin sludge. Bawul ɗin sarrafa solenoid yana ƙara haɓaka maida hankali don ingantaccen aikin dewatering.

1. Zane-Yancin Clog tare da Zobba Masu Tsabtace Kai

HLDS tana amfani da zobba masu motsi da kafaffen riguna maimakon tacewa, kawar da al'amuran toshewa da rage bukatun kulawa. Yana da dacewa musamman ga sludge mai mai da ƙananan hankali, kuma yana buƙatar rashin tsaftacewa mai tsanani, rage ƙazanta na biyu.

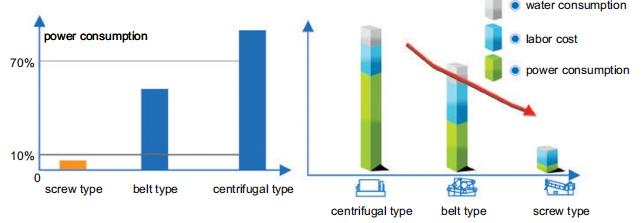

2. Ƙarƙashin Sauri, Aiki Mai Ingantacciyar Makamashi

Tare da saurin juyawa da yawa ƙasa da na bel ko tsarin centrifugal, HLDS screw press yana rage yawan amfani da makamashi har zuwa 87.5% idan aka kwatanta da matsi na bel da 95% idan aka kwatanta da centrifuges. Hakanan yana haifar da ƙarancin hayaniya yayin aiki.

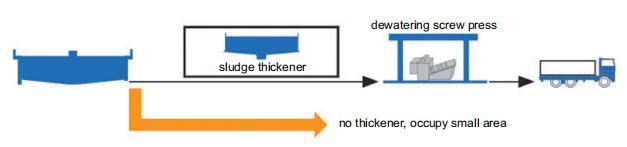

3. Rage kayan more rayuwa & Kudin aiki

The dunƙule sludge dewatering inji iya bi da sludge kai tsaye daga aeration da sedimentation tankuna, kawar da bukatar thickening tankuna da kuma rage phosphorus saki. Yana buƙatar ƙasan filin bene, yana haifar da ƙarancin saka hannun jari a wuraren kula da ruwan sha.

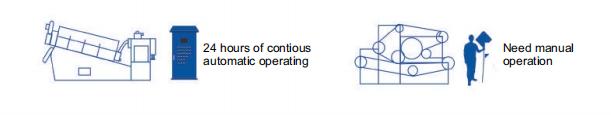

4. Sarrafa Mai sarrafa kansa & Aiki Mai Sauƙi

Haɗewa tare da majalisar kula da wutar lantarki na tushen PLC, tsarin yana goyan bayan cikakken aiki mai sarrafa kansa. Rashin abubuwan da ke tattare da toshewa yana tabbatar da kwanciyar hankali, ƙarancin kulawa - madaidaici don wuraren da ke buƙatar aikin 24/7 ba tare da kulawa ba.

Aikace-aikace:

Latsa maballin cire ruwa yana da matukar dacewa kuma yana da amfani ga nau'ikan sludge da masana'antu da yawa:

- ✅ Maganin ruwan sha na karamar hukuma

- ✅ Petrochemical & Chemical masana'antu

- ✅ Injin gwangwani & takarda

- ✅ Magungunan magunguna da rini

- ✅ sarrafa nama & kiwo

- ✅ Hako ma'adinan ruwa

- ✅ Masana'antun bugawa da zane-zane

- ✅ sludge tanki

- ✅ Man dabino da sharar gonakin kiwo

Ko kuna sarrafa sludge mai kunnawa, sludge DAF, gauraye sludge, ko sludge mai haɗe-haɗe da sinadarai, wannan na'ura mai lalata ruwa tana tabbatar da ingantaccen aiki da dawowa kan saka hannun jari.

Ma'aunin Fasaha:

| Nau'in | Ruwan Sharar Danye / Sharar Da Aka Kunna Lalacewa / Tsaftace Tsakanin Kemikal | Narkar da Jirgin Sama | Mixed Raw Sludge | ||

| Ƙarfafawa (TS) | 0.20% | 1.00% | 2.00% | 5.00% | 3.00% |

| HLDS-131 | ~4kg-DS/h(~2.0m³/h) | ~6kg-DS/h(~0.6m³/h) | ~10kg-DS/h(~0.5m³/h) | ~20kg-DS/h(~0.4m³/h) | ~26kg-DS/h(~0.87m³/h) |

| HLDS-132 | ~8kg-DS/h(~4.0m³/h) | ~12kg-DS/h(~1.2m³/h) | ~20kg-DS/h(~1.0m³/h) | ~40kg-DS/h(~0.5m³/h) | ~52kg-DS/h(~1.73m³/h) |

| HLDS-133 | ~12kg-DS/h(~6.0m³/h) | ~18kg-DS/h(~1.8m³/h) | ~30kg-DS/h(~1.5m³/h) | ~60kg-DS/h(~1.2m³/h) | ~72kg-DS/h(~2.61m³/h) |

| HLDS-201 | ~8kg-DS/h (~4.0m³/h) | ~12kg-DS/h(~1.2m³/h) | ~20kg-DS/h(~1.0m³/h) | ~40kg-DS/h(~0.8m³/h) | ~52kg-DS/h(~1.73m³/h) |

| HLDS-202 | ~ 16kg-DS/h (~8.0m³/h) | ~24kg-DS/h(~2.4m³/h) | ~40kg-DS/h(~2.0m³/h) | ~80kg-DS/h(~1.6m³/h) | ~104kg-DS/h(~3.47m³/h) |

| HLDS-203 | ~ 24kg-DS/h (~ 12.0m³/h) | ~36kg-DS/h(~3.6m³/h) | ~60kg-DS/h(~3.0m³/h) | ~120kg-DS/h(~2.4m³/h) | ~156kg-DS/h(~5.20m³/h) |

| HLDS-301 | ~20kg-DS/h (~10.0m³/h) | ~30kg-DS/h(~3.0m³/h) | ~50kg-DS/h(~2.5m³/h) | ~100kg-DS/h(~2.0m³/h) | ~130kg-DS/h(~4.33m³/h) |

| HLDS-302 | ~40kg-DS/h (~20.0m³/h) | ~60kg-DS/h(~6.0m³/h) | ~100kg-DS/h(~5.0m³/h) | ~200kg-DS/h(~4.0m³/h) | ~260kg-DS/h(~8.67m³/h) |

| HLDS-303 | ~ 60kg-DS/h (~30.0m³/h) | ~90kg-DS/h(~9.0m³/h) | ~150kg-DS/h(~7.5m³/h) | ~300kg-DS/h(~6.0m³/h) | ~390kg-DS/h(~13.0m³/h) |

| HLDS-304 | ~80kg-DS/h (~40.0m³/h) | ~120kg-DS/h(~12.0m³/h) | ~200kg-DS/h(~10.0m³/h) | ~400kg-DS/h(~8.0m³/h) | ~520kg-DS/h(~17.3m³/h) |

| HLDS-351 | ~40kg-DS/h (~20.0m³/h) | ~60kg-DS/h(~6.0m³/h) | ~100kg-DS/h(~5.0m³/h) | ~200kg-DS/h(~4.0m³/h) | ~260kg-DS/h(~8.67m³/h) |

| HLDS-352 | ~80kg-DS/h (~40.0m³/h) | ~120kg-DS/h(~12.0m³/h) | ~200kg-DS/h(~10.0m³/h) | ~400kg-DS/h(~8.0m³/h) | ~520kg-DS/h(~17.3m³/h) |

| HLDS-353 | ~ 120kg-DS/h (~ 60.0m³/h) | ~180kg-DS/h(~18.0m³/h) | ~300kg-DS/h(~15.0m³/h) | ~600kg-DS/h(~12.0m³/h) | ~780kg-DS/h(~26.0m³/h) |

| HLDS-354 | ~ 160kg-DS/h (~80.0m³/h) | ~ 240kg-DS/h(~24.0m³/h) | ~400kg-DS/h(~20.0m³/h) | ~800kg-DS/h(~16.0m³/h) | ~1040kg-DS/h(~34.68m³/h) |

| HLDS-401 | ~70kg-DS/h (~35.0m³/h) | ~100kg-DS/h(~10m³/h) | ~170kg-DS/h(~8.5m³/h) | ~340kg-DS/h(~6.5m³/h) | ~442kg-DS/h(~16.0m³/h) |

| HLDS-402 | ~135kg-DS/h(~67.5m³/h) | ~200kg-DS/h(~20.0m³/h) | ~340kg-DS/h(~17.0m³/h) | ~680kg-DS/h(~13.6m³/h) | ~884kg-DS/h(~29.5m³/h) |

| HLDS-403 | ~200kg-DS/h(~100m³/h) | ~300kg-DS/h(~30.0m³/h) | ~510kg-DS/h(~25.5m³/h) | ~1020kg-DS/h(~20.4m³/h) | ~ 1326kg-DS/h(~44.2m³/h) |

| HLDS-404 | ~ 266kg-DS/h (~ 133m³/h) | ~400kg-DS/h(~40.0m³/h) | ~680kg-DS/h(~34.0m³/h) | ~1360kg-DS/h(~27.2m³/h) | ~1768kg-DS/h(~58.9m³/h) |

| Nau'in | Tsawon Zuciya | Girma | Nauyi (kg) | Ƙarfi (kW) | Ruwan Wanke (L/h) | |||

| L (mm) | W (mm) | H(mm) | Babu komai | Aiki | ||||

| HLDS-131 | 250 | 1860 | 750 | 1080 | 180 | 300 | 0.2 | 24 |

| HLDS-132 | 250 | 1960 | 870 | 1080 | 250 | 425 | 0.3 | 48 |

| HLDS-133 | 250 | 1960 | 920 | 1080 | 330 | 580 | 0.4 | 72 |

| HLDS-201 | 350 | 2510 | 900 | 1300 | 320 | 470 | 1.1 | 32 |

| HLDS-202 | 350 | 2560 | 1050 | 1300 | 470 | 730 | 1.65 | 64 |

| HLDS-203 | 350 | 2610 | 1285 | 1300 | 650 | 1100 | 2.2 | 96 |

| HLDS-301 | 495 | 3330 | 1005 | 1760 | 850 | 1320 | 1.3 | 40 |

| HLDS-302 | 495 | 3530 | 1290 | 1760 | 1300 | 2130 | 2.05 | 80 |

| HLDS-303 | 495 | 3680 | 1620 | 1760 | 1750 | 2880 | 2.8 | 120 |

| HLDS-304 | 495 | 3830 | 2010 | 1760 | 2300 | 3850 | 3.55 | 160 |

| HLDS-351 | 585 | 4005 | 1100 | 2130 | 1100 | 1900 | 1.3 | 72 |

| HLDS-352 | 585 | 4390 | 1650 | 2130 | 1900 | 3200 | 2.05 | 144 |

| HLDS-353 | 585 | 4520 | 1980 | 2130 | 2550 | 4600 | 2.8 | 216 |

| HLDS-354 | 585 | 4750 | 2715 | 2130 | 3200 | 6100 | 3.55 | 288 |

| HLDS-401 | 759 | 4680 | 1110 | 2100 | 1600 | 3400 | 1.65 | 80 |

| HLDS-402 | 759 | 4960 | 1760 | 2100 | 2450 | 5200 | 2.75 | 160 |

| HLDS-403 | 759 | 5010 | 2585 | 2100 | 3350 | 7050 | 3.85 | 240 |

| HLDS-404 | 759 | 5160 | 3160 | 2100 | 4350 | 9660 | 4.95 | 320 |

-

Wakilin Deodorizing don Tankunan Septic & Sharar gida...

-

Ingantacciyar Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙaƙwalwa

-

Wakilin Nitrifying Bacteria don Maganin Ruwan Shara

-

Allon A tsaye don Rarraba Ruwan Ruwa mai ƙarfi...

-

Halotolerant Bacteria - Advanced Bioremed...

-

Allon Bar Injin don Wastewater Pretreatme...