Mahimman Sifofi

-

✅Jet Mixer- Yana tabbatar da daidaituwar polymers mai ƙarfi.

-

✅Mita Mai Daidaito na Ruwa– Yana tabbatar da daidaiton rabon narkewar abinci.

-

✅Kayan Tanki Masu Sauƙi- An keɓance shi bisa ga buƙatun aikace-aikace.

-

✅ Nau'ikan kayan haɗi iri-iri- Yana tallafawa buƙatun shigarwa daban-daban.

-

✅Shigarwa Mai Modular– Sanya kayan aiki masu sassauƙa da kuma wurin allurar magani.

-

✅Ka'idojin Sadarwa- Yana tallafawa Profibus-DP, Modbus, da Ethernet don haɗakarwa mara matsala tare da tsarin sarrafawa na tsakiya.

-

✅Na'urar auna matakin Ultrasonic– Gano matakin da ba a taɓawa ba kuma abin dogaro a cikin ɗakin allurai.

-

✅Haɗakar Tashar Allura– Ƙarfin jituwa da tsarin allurar bayan shiri.

-

✅An yi oda don yin oda– Magani da aka keɓance bisa ga buƙatun allurai na musamman ga abokin ciniki, kamar ƙimar ciyar da polymer (kg/h), yawan maganin, da lokacin balaga.

Aikace-aikace na yau da kullun

-

✔️Tarin ruwa da kuma toshewar ruwa a wuraren sarrafa ruwan sha da kuma wuraren shan ruwa

-

✔️Alamar polymer don kauri da kuma cire ruwa daga ƙasa

-

✔️Ingantaccen aiki a tsarin allurar sinadarai don cibiyoyin masana'antu da na birni

-

✔️Ya dace da amfani da famfunan allurar polymer, famfunan auna sinadarai, da tsarin allurar sinadarai ta atomatik

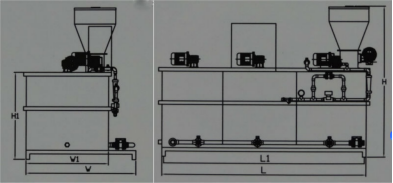

Sigogi na Fasaha

| Samfuri/Siffa | HLJY500 | HLJY1000 | HLJY1500 | HLJY2000 | HLJY3000 | HLJY4000 | |

| Ƙarfin aiki (L/H) | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | |

| Girma (mm) | 900*1500*1650 | 1000*1625*1750 | 1000*2240*1800 | 1220*2440*1800 | 1220*3200*2000 | 1450*3200*2000 | |

| Ƙarfin Mai Naɗa Foda (KW) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | |

| Dia na Paddle (φmm) | 200 | 200 | 300 | 300 | 400 | 400 | |

| Haɗa Motar | Gudun Dogon Doki (r/min) | 120 | 120 | 120 | 120 | 120 | 120 |

| Ƙarfi (KW) | 0.2*2 | 0.2*2 | 0.37*2 | 0.37*2 | 0.37*2 | 0.37*2 | |

| Dia Bututun Shiga DN1(mm) | 25 | 25 | 32 | 32 | 50 | 50 | |

| Dia bututun fitarwa DN2(mm) | 25 | 25 | 25 | 25 | 40 | 40 | |