Bidiyon Samfuri

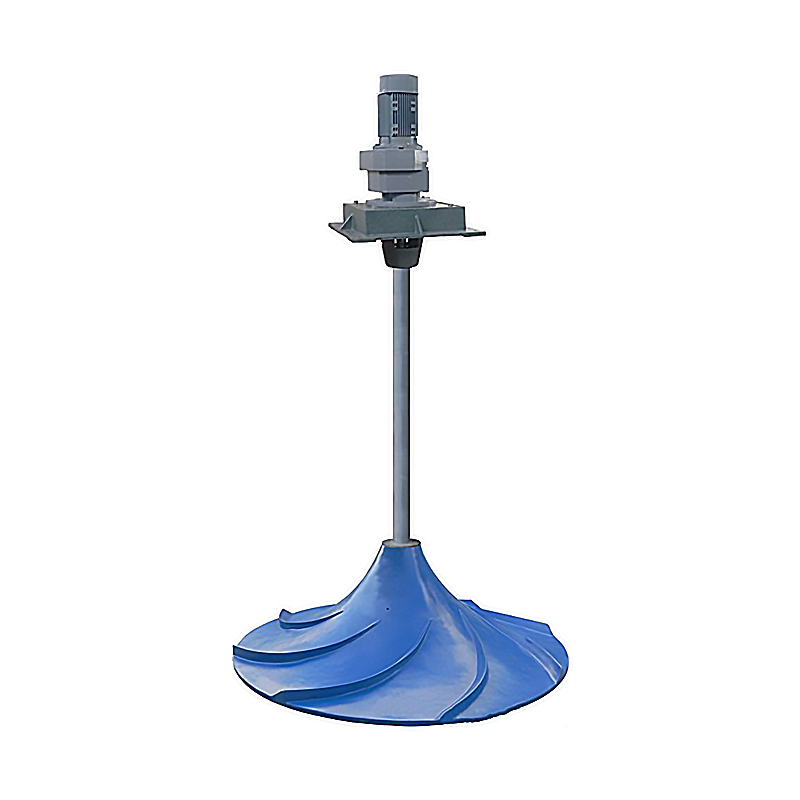

Bayanin Tsarin

Injin haɗa hyperboloid ya ƙunshi manyan abubuwan da ke gaba:

-

1. Na'urar watsawa

-

2. Impeller

-

3. Tushe

-

4. Tsarin ɗagawa

-

5. Na'urar sarrafa wutar lantarki

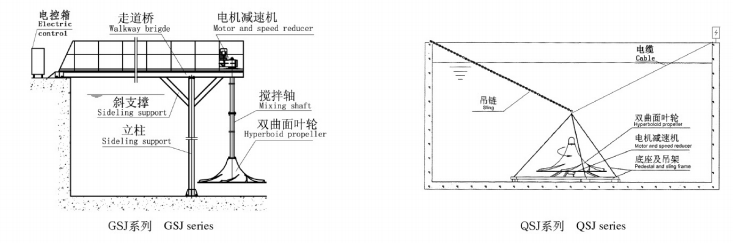

Don duba zane-zanen tsarin, duba waɗannan zane-zanen:

Fasallolin Samfura

✅ Gudun juyawa mai girma uku don haɗawa mai inganci ba tare da wuraren da ba su da matattun wurare ba

✅ Babban abin da ke haifar da zafi a saman jiki tare da ƙarancin amfani da wutar lantarki—mai inganci da kuzari

✅ Shigarwa mai sassauƙa da kuma sauƙin kulawa don samun sauƙin amfani

Aikace-aikace na yau da kullun

Masu haɗa nau'ikan QSJ da GSJ sun fi dacewa da tsarin tsaftace ruwan shara, gami da amma ba'a iyakance ga:

Tafkunan Anaerobic

Tankunan zubar da ruwa na coagulation

Tafkunan Denitrification

Tankunan daidaitawa

Tankunan Nitrification

Sifofin Samfura

| Nau'i | Diamita na Tumfafi (mm) | Saurin Juyawa (r/min) | Ƙarfi (kW) | Yankin Sabis (m²) | Nauyi (kg) |

| GSJ/QSJ | 500 | 80-200 | 0.75 -1.5 | 1-3 | 300/320 |

| 1000 | 50-70 | 1.1 -2.2 | 2-5 | 480/710 | |

| 1500 | 30-50 | 1.5-3 | 3-6 | 510/850 | |

| 2000 | 20-36 | 2.2-3 | 6- 14 | 560/1050 | |

| 2500 | 20-32 | 3-5.5 | 10-18 | 640/1150 | |

| 2800 | 20-28 | 4-7.5 | 12-22 | 860/1180 |